Market Overview

The Printed Electronics Devices Market is experiencing substantial growth due to increasing adoption across multiple industries. In 2024, the market size is estimated to be USD 9,564 million, and it is projected to reach USD 31,571.65 million by 2032, growing at a CAGR of 16.1% from 2024 to 2032. The rising demand for flexible, lightweight, and cost-effective electronic solutions is driving this expansion. Companies are investing heavily in research and development to improve printed electronic materials and manufacturing processes, ensuring enhanced performance and scalability. The demand for printed electronic devices is particularly strong in consumer electronics, healthcare, automotive, and packaging industries, where advanced functionalities are increasingly required.

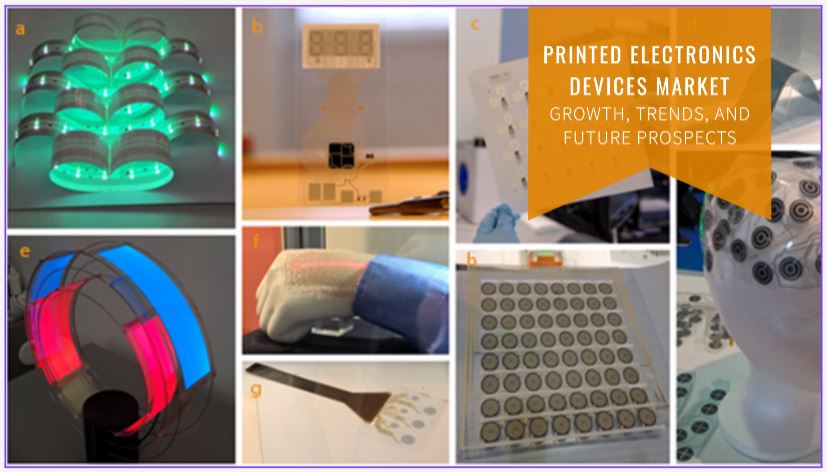

Printed electronics provide an innovative manufacturing approach by enabling thin, lightweight, and flexible electronic components. This technology facilitates cost-effective production while maintaining high efficiency and performance. Traditional electronic manufacturing processes are labor-intensive and require complex assembly lines, whereas printed electronics streamline production with reduced material wastage. Furthermore, the ability to print electronics on various substrates, including plastics and textiles, has unlocked new applications such as wearable technology, smart packaging, and digital displays. These advancements position printed electronics as a transformative force in the global electronics industry.

In addition to commercial applications, printed electronics have gained prominence in healthcare, where they are being used for biosensors, diagnostic devices, and smart bandages. These developments are improving patient monitoring and treatment, reducing dependency on traditional medical equipment. The automotive sector is also benefiting, with printed electronics being integrated into smart dashboards, flexible sensors, and in-car entertainment systems. This growing adoption across multiple sectors indicates that the market will continue to expand rapidly in the coming years.

Despite its immense potential, the printed electronics market faces challenges such as high initial investment costs and complex manufacturing processes. However, continuous technological advancements, material improvements, and increasing economies of scale are expected to mitigate these challenges over time. As research continues to refine printing techniques and enhance material properties, the adoption of printed electronics will become more widespread, solidifying its role as a key technology in the future of electronics manufacturing.

Dive into the full report: https://www.credenceresearch.com/report/printed-electronics-devices-market

Market Drivers

Rising Demand for Flexible and Lightweight Electronics

The increasing demand for lightweight, flexible, and cost-efficient electronic components is one of the primary drivers of the Printed Electronics Devices Market. Unlike traditional rigid circuits, printed electronics allow for bendable, stretchable, and ultra-thin electronic components, which are essential for modern applications. This is particularly beneficial for industries such as wearable technology, automotive displays, and smart textiles, where flexibility plays a crucial role. The ability to print circuits on a variety of substrates, including plastic, glass, and even fabric, makes printed electronics a versatile solution for futuristic applications. Companies are actively investing in flexible electronics research, leading to innovations in stretchable sensors, foldable displays, and interactive packaging solutions.

Growing Adoption in the Healthcare Industry

The healthcare sector is a significant contributor to the growth of printed electronics. Medical applications such as biosensors, wearable monitors, and drug delivery patches are increasingly using printed electronic components. The demand for real-time health monitoring, coupled with advancements in medical diagnostics, has accelerated the adoption of printed electronics in healthcare. Companies are developing disposable and biodegradable printed sensors, which provide cost-effective solutions for patient monitoring. Moreover, printed electronics enable miniaturization and improved portability of medical devices, making them more accessible to patients. Government funding and initiatives to support digital healthcare solutions further enhance the market’s expansion.

Advancements in Printed Electronics Materials

The development of high-performance conductive inks and advanced substrates is another major market driver. Printed electronics rely on innovative materials such as silver nanoparticle inks, carbon-based conductive materials, and hybrid polymers, which offer superior conductivity and flexibility. These materials enhance the efficiency and durability of printed electronic components, making them viable for large-scale industrial applications. Moreover, new advancements in 3D-printed electronics allow manufacturers to produce multilayer circuits with improved performance. Research institutions and private companies are collaborating to develop cost-efficient and environmentally friendly conductive inks, further driving market growth.

Increasing Demand for Energy-Efficient Technologies

Printed electronics support sustainable and energy-efficient innovations, making them an attractive alternative to traditional electronics. The ability to produce thin-film solar cells, smart lighting systems, and printed batteries has led to increased investments in energy-efficient solutions. The global push for green energy and reduced carbon emissions has also accelerated the adoption of printed electronics in solar energy and energy storage applications. Flexible printed photovoltaics are being integrated into smart buildings and IoT devices, reducing dependence on traditional power sources. As the demand for sustainable electronics increases, printed electronics will play a crucial role in the transition toward energy-efficient and eco-friendly technologies.

Market Challenges

High Initial Investment and Manufacturing Costs

Despite its advantages, the printed electronics market faces high production and initial investment costs. The development of conductive inks, advanced substrates, and precision printing techniques requires significant R&D spending. Companies must invest in high-end printing machinery and trained personnel to ensure efficiency and reliability. Small and mid-sized enterprises struggle to compete due to expensive material procurement and high equipment costs. However, as production scales up and printing technologies advance, manufacturing costs are expected to decrease over time.

Limited Durability and Performance Issues

One of the major concerns with printed electronics is durability and performance reliability. Printed circuits are susceptible to environmental factors such as moisture, temperature fluctuations, and physical stress, leading to degradation over time. Traditional silicon-based electronics still offer superior durability and performance under extreme conditions, making them preferable for critical applications such as aerospace and industrial automation. Continuous research is focused on improving material resilience, but until these challenges are fully addressed, adoption in high-end applications will remain limited.

Regulatory and Standardization Issues

The absence of global standardization and regulatory frameworks for printed electronics poses a significant challenge. Different regions have varying regulations for electronic components, making it difficult for companies to expand internationally. Compliance with safety and performance standards is crucial for medical and automotive applications, where reliability is paramount. Governments and industry bodies are working toward harmonizing regulations, but the lack of uniformity currently slows down product approvals and market penetration.

Technological Limitations in Large-Scale Production

While printed electronics offer cost-effective production, challenges remain in scaling up manufacturing for mass production. The limited precision of current printing techniques can lead to inconsistent performance in large-scale applications. As a result, industries requiring high-precision electronics, such as aerospace and defense, remain hesitant to adopt printed electronics. Overcoming these technological limitations requires significant advancements in printing resolution, material consistency, and process automation.

Market Opportunities

Expansion in IoT and Smart Packaging

The rise of the Internet of Things (IoT) has opened new opportunities for printed electronics in smart packaging, interactive labels, and embedded sensors. These applications allow manufacturers to create real-time tracking and data collection systems, enhancing supply chain visibility. Smart packaging with NFC and RFID tags is gaining traction in the retail and pharmaceutical sectors, offering enhanced security and traceability. Printed NFC sensors for contactless transactions are also expected to witness increased adoption.

Growth in Printed Wearable Electronics

The demand for wearable technology continues to rise, with applications in health monitoring, fitness tracking, and augmented reality (AR) devices. Printed electronics enable the development of flexible, stretchable, and lightweight wearable sensors. E-textiles embedded with printed circuits are becoming popular in sports and military applications, providing real-time performance monitoring and environmental sensing.

Integration with 3D Printing

The combination of 3D printing and printed electronics is a game-changer for customized electronic device manufacturing. Companies are exploring fully 3D-printed circuits, which offer superior design flexibility and reduced material waste. Hybrid printing solutions integrating 3D-printed components with printed electronics are expected to gain widespread adoption.

Growing Investment in Sustainable Electronics

With increasing environmental awareness, the demand for biodegradable and recyclable printed electronics is growing. Companies are developing organic-based conductive inks and eco-friendly substrates to reduce electronic waste. The development of biodegradable printed sensors will be a key focus in the coming years.

Market Segmentation

By Technology

- Inkjet Printing

- Screen Printing

- Flexography

- Gravure Printing

By Application

- Consumer Electronics

- Healthcare

- Automotive

- Packaging

By Material Type

- Conductive Inks

- Substrates

By End-User

- Consumer Electronics

- Healthcare

- Automotive

- Packaging

By Region

- North America

- U.S.

- Canada

- Mexico

Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

Latin America

- Brazil

- Argentina

- Rest of Latin America

Middle East & Africa

- GCC Countries

- South Africa

- Rest of Middle East and Africa

Regional Analysis

North America

North America remains one of the leading regions in the Printed Electronics Devices Market, driven by high R&D investments, a strong industrial base, and increasing demand for flexible electronics. The United States dominates the regional market due to the presence of major printed electronics manufacturers, startups, and research institutions actively developing next-generation printed electronic components. Companies in this region are investing heavily in conductive ink development, advanced printing techniques, and scalable manufacturing solutions to improve product performance and reduce costs.

The healthcare sector in North America has seen significant adoption of printed electronics in biosensors, digital health monitoring devices, and drug delivery systems. The demand for smart packaging and RFID technology is also surging in the retail and logistics sectors, contributing to market growth. Government initiatives, such as funding for energy-efficient technologies, are supporting the integration of printed electronics in smart grids, solar energy applications, and IoT-based solutions. Additionally, leading universities and research institutes are collaborating with industries to drive material innovation and technology scalability.

Europe

Europe has emerged as a major hub for sustainable and eco-friendly printed electronics. Countries such as Germany, the UK, and France are spearheading the adoption of biodegradable printed electronics, recyclable conductive inks, and energy-efficient printed displays. The European Union’s Green Deal initiatives are pushing for greater use of printed photovoltaics and smart lighting solutions to reduce energy consumption.

The automotive sector in Europe is also a key driver for printed electronics. Major automakers are integrating printed sensors, flexible dashboards, and OLED-based lighting solutions into next-generation vehicles. The demand for lightweight and flexible electronic components is growing as automakers focus on electric and autonomous vehicles. Moreover, smart textiles and e-textiles for sportswear and medical applications are gaining traction across European markets, further driving innovation in printed electronics.

Asia-Pacific

The Asia-Pacific region is experiencing the fastest growth in the Printed Electronics Devices Market, fueled by rapid industrialization, a booming consumer electronics sector, and government-backed technological advancements. China, Japan, South Korea, and India are leading the charge in manufacturing flexible displays, printed circuit boards (PCBs), and advanced semiconductor components.

China, as the world’s largest electronics manufacturing hub, has heavily invested in printed OLED displays, RFID-based smart packaging, and flexible sensors for industrial applications. South Korea and Japan are at the forefront of wearable technology, foldable smartphones, and automotive printed electronics. India, on the other hand, is emerging as a key market for low-cost printed electronics solutions in healthcare, agriculture, and renewable energy. Governments in these countries are providing subsidies and grants to promote printed electronics research and development, ensuring long-term growth.

Latin America

Latin America is gradually embracing printed electronics technology, especially in healthcare, logistics, and IoT applications. Brazil, Mexico, and Argentina are leading regional developments in wearable biosensors, smart medical patches, and low-cost printed RFID systems. The rising penetration of IoT-based smart packaging in the food and beverage industry is also contributing to market expansion.

Government initiatives to improve healthcare infrastructure and digital transformation are fueling demand for printed medical devices. Additionally, the renewable energy sector in Latin America is exploring printed solar cells and flexible energy storage solutions to enhance sustainability. However, limited R&D investments and the slow adoption of advanced printing technologies pose challenges to market growth in this region.

Middle East & Africa

The Middle East & Africa region is witnessing gradual adoption of printed electronics, primarily driven by smart infrastructure projects, sustainable energy solutions, and growing industrial automation. The UAE and Saudi Arabia are investing in printed photovoltaics for smart cities, aiming to reduce carbon footprints and promote energy efficiency.

The healthcare industry in Africa is increasingly using affordable printed biosensors and medical diagnostic tools to improve patient care in remote areas. The wearable electronics market is also expanding as consumers seek smart fitness and health monitoring solutions. Despite these opportunities, lack of skilled labor, high material costs, and limited manufacturing capabilities continue to hinder the widespread adoption of printed electronics in this region.

Top Companies

- DuPont de Nemours, Inc.

- Printed Electronics Limited

- Avery Dennison Corporation

- Samsung Electronics

- PARC (Palo Alto Research Center Incorporated)

- Kodak (Eastman Kodak Company)

- Thin Film Electronics ASA

- LG Display

- Novacentrix

- Hansol Technics Co., Ltd.

Future Outlook

- The future of printed electronics will be heavily influenced by next-generation conductive inks, including graphene-based inks, silver nanowires, and carbon nanotubes. These materials will significantly enhance flexibility, conductivity, and durability, making printed electronics more viable for industrial applications.

- The combination of 3D printing and printed electronics will revolutionize custom electronic device manufacturing. Future innovations will focus on fully 3D-printed electronic circuits, allowing for rapid prototyping and reduced material wastage.

- Flexible OLED and e-paper displays will see increased adoption across wearable devices, automotive dashboards, and smart signage. Printed displays will become a mainstream component in next-generation consumer electronics.

- The expansion of the Internet of Things (IoT) will drive demand for printed temperature sensors, RFID tags, and NFC-enabled circuits in logistics, healthcare, and smart home applications.

- Future trends will focus on eco-friendly printed electronics, including biodegradable conductive inks and recyclable substrates. The move toward sustainable materials will be a key differentiator in the market.

- The automotive industry will witness an increase in printed sensors, flexible displays, and OLED-based lighting solutions in EVs. These components will enhance energy efficiency and vehicle aesthetics while reducing weight.

- The packaging industry will adopt printed RFID labels, QR codes, and NFC tags for real-time tracking and anti-counterfeiting measures in industries such as pharmaceuticals and food & beverages.

- The future will see an increase in printed biosensors, smart patches, and flexible ECG monitors for real-time health tracking. Printed e-textiles will also become popular in the sports and fitness industry.

- Innovations in printed energy storage solutions, such as thin-film batteries and flexible supercapacitors, will enhance portable power solutions for IoT devices and medical wearables.

- As printed electronics continue to evolve, government funding, university research programs, and private sector collaborations will play a crucial role in accelerating technological advancements and commercialization.

Dive into the full report: https://www.credenceresearch.com/report/printed-electronics-devices-market